Safety Helmet

Place of Origin: Mainland China

Model Number: CG-14

Material: Durable ABS shell+ 6 points suspension cradle

Air vents: 16, Sliding vent holes allow easy opening and closing based on weather conditions!

Weight: 485g

Certification: ANSI Z89.1 TYPE I CLASS C

Age group: Adults

Color/graphics:Customized

Size: One size fits most 53-63cm

Accessories: High strengthen Size adjustment, Nylon Chin strap, egyptian cotton core sweatband.

Best use: work at height, industrial, constructio

Product Parameters

| Model Number | CG-14 full birm industrial safety helmet |

| Material | ABS shell + 6 points suspension webbing +soft sweatband |

| Inner Pads | Washable egyptian cotton core sweatband |

| Chin Strap | Adjustable Nylon/PP strap for a perfect fitness |

| Buckle | Quick release buckle |

| Head circumference | 53-63cm one size fits most |

| Weight | 485g |

| Logo custom | Pad print, epoxy(dome) sticker, UV-drt sticker |

| Master carton size | 56*45*51cm |

| Packaging | 20pcs/per carton |

| Price term | EXW/FOB |

| Shipping | Sample by courier, bulk production by air freight or ocean freight |

| Payment terms | T/T, western union, paypal |

| Lead time | 40-45 days |

| Feature | Unisex/ ANSI/ISEA Z89.1 TYPE I CLASS C/Top quality/ OEM/ ODM |

| Best use | construction, height safety, scaffolding |

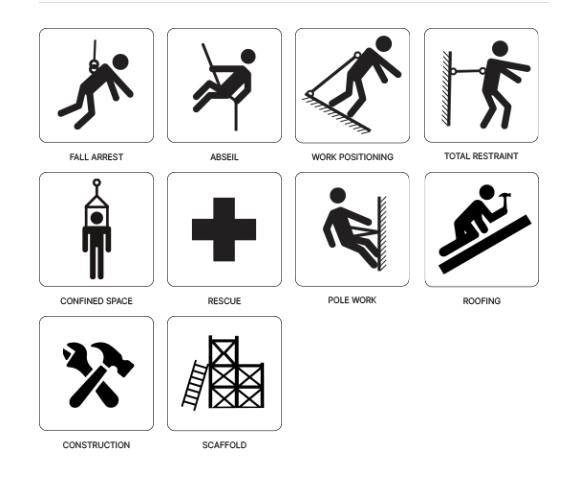

The Application area of safety helmet:

Suitable for construction, mining work, tree climbing work, woodworking, mechanics, forestry, manufacturing, height and scaffolding work in any trade that requiring general head protection.

Description:

Lightweight, Durable, Vented Hard Hat

This full brim construction hard hat helmet is made of high impact penetration resistant ABS materials, Hard shell, Durable. Superior quality provide excellent head protection,protect your head from mishaps and accidents. Sliding vent holes allow easy opening and closing based on weather conditions, allow air to flow and keep head cool.

Design that combines safety with fashion appearance

This construction safety helmet features a full brim design with a wide profile, which provides better protection from glare, direct sunlight (ultraviolet rays), rain, and windblown sand. The front, back, and side areas are equipped with high-visibility reflective tape, which enhances the user's visibility in low light conditions. The custom water transfer print pattern makes the safety helmet more unique and attractive. ( Support to customize your logo, pattern and reflective sticker design)

ONE SIZE FITS MOST

Adjustable ratchet design allows to quickly find the right fit for your head shape. this construction helmet meets ANSI Z89.1 Type 1 Class C standards, suitable for industrial applications and is an ideal choice for construction sites and their surrounding areas.

Safe and comfortable wearing experience

Equipped with an adjustable 6-point suspension system to enhance shock absorption and overall comfort. The replaceable soft Egyptian cotton sweat-absorbing strap is made of perforated coating to absorb sweat to the maximum extent, so that workers can wear comfortably throughout their workday. The convenient and comfortable headband design is equipped with a moldable chin cup, providing additional safety and stability. And it is easy to remove.

Customization Support:

We offer comprehensive customization services, including color, logo, packaging, and pattern printing, etc. to meet your specific requirements.

Factory Size & Workforce

Total area: 18,000 m²

Total employees: 210

Dongguan Factory: approx. 200 staff (50 office staff, 150 production workers)

Yueyang Factory: approx. 150 staff (35 office staff, 115 production workers)

Production Equipment & Capabilities

In-house capabilities include mold manufacturing, printing, vacuum forming, injection molding, in-mold production, painting, labeling, and packaging (partial outsourcing for specialized packaging).

Production Capacity

Daily Output: 5,000 helmets

Monthly Output: approx. 150,000 helmets

Quality Control Process

Pre-production sample completed before mass production

Customer approval based on signed sample

Mass production strictly follows approved reference

Third-party inspection arranged by customers (full inspection or random sampling) before shipment

International Certifications

CE EN1078 | CPSC | ASTM | AS/NZS | UKCA

Annual Sales Turnover

Approx. RMB 95 million

Main Product Categories

Bicycle helmets

Ski helmets

Equestrian helmets

Riot helmets

Industrial safety helmets

Climbing helmets

Water sports helmets

Skydiving helmets

Export Markets

Switzerland, Sweden, Czech Republic, Germany, United Kingdom, United States, Japan, Norway, Italy, France, Netherlands, Indonesia, Singapore, Thailand, and Australia

Key Partners & Brands

SWEET (Norway): Ski helmets, cycling helmets, water helmets, protective helmets

AGU (Netherlands): Cycling helmets, safety helmets

GIANT (China): Bicycle helmets, safety helmets

LIIMAR (Italy): Cycling helmets, safety helmets

Helmet Quality Control Process

At CGPRO Helmets, every helmet undergoes a comprehensive, multi-stage quality inspection process to ensure consistent safety, durability, and international compliance. From raw material to final packaging, we enforce strict control measures to guarantee outstanding product quality for global clients.

1. Incoming Quality Control (IQC)

All raw materials are tested upon arrival to meet strict safety and performance criteria.

EPS foam density & consistency

PC/ABS shell material verification (impact & burn test)

Webbing and buckle tensile strength testing

Non-toxic ink & decal inspection (odor and adhesion check)

2. In-Process Quality Control (IPQC)

We implement process checks at each key production stage to prevent defects from entering the next phase.

Injection molding: Surface flatness, no cracks or shrink marks

EPS shaping: Uniform thickness and bonding quality

In-mold shell & EPS bonding strength

Interior padding alignment, sewing, and glue adhesion

3. Final Quality Control (FQC)

Before packaging, all helmets are fully inspected for overall quality, fit, and function.

100% visual inspection for appearance

Shell stability and deformation test

Strap & adjustment system function test

Size and fitting confirmation using model headforms

4. Laboratory Testing (EN/ASTM/CE/ISO Standards)

Our in-house lab and third-party partners conduct critical safety tests in accordance with international certifications.

Impact absorption test (EN1078 / ASTM F1447 / EN397)

Penetration resistance (EN12492 / EN1385)

Chin strap strength and retention system durability

High/low temperature resistance and UV stability

5. Outgoing Quality Control (OQC)

Before shipping, we conduct random sampling inspections to ensure batch consistency and package integrity.

AQL-based visual & functional check

Barcode, label, and accessory verification

Final inspection report and shipping approval

Case: OEM Polo Helmet with Carbon Fiber Shell & Retractable Visor

Client Need:

In July 2024, a Dubai-based polo helmet client approached us, seeking an OEM & ODM manufacturer capable of delivering a fully customized solution. Their requirements included a wide brim, retractable sun visor, lightweight design, and certification under PAS and SEI standards.

Our Solution:

After a detailed review of the client’s needs, we created a 3D model and produced 3D-printed prototypes to confirm structure and aesthetics. Upon approval, we developed four size molds. To ensure certification readiness while achieving lightweight performance, we recommended a 100% carbon fiber outer shell paired with a high-performance, lightweight EPP liner. The retractable visor was engineered as a signature feature of the helmet.

Result:

The helmet is currently in the testing phase. The client has expressed strong satisfaction with the design and engineering approach, and collaboration is expected to expand once certification is complete.

We have set up a design department in order to meet the different customers;

Our designers will design the most creative and most innovative helmet in different styles one step ahead the market trends and meets the safety standards, such as CPSC, CE and ASTM. Our sales department and Customer Services provide all the needs to take care of Quality Control and On Time Delivery for Domestic and International market. What's more, we have our own EPS molding plant