Equestrian Helmet

• Place of Origin: China (Mainland)

• Model Number: HR02 Horse Riding Helmets

• Material: EPS + ABS + Removable inner mesh cap

• Color: PANTONE color is available

• Strap: High quality leather

• Buckle:ITW NEXUS buckle

• Size: XS-S(49-54cm); S-M(54-58CM); L-XL(58-62CM)

• Certificate: CE EN1384:2017&ASTM

• Best use: horse riding, equestrian

Horse Riding Helmet

Our horse riding helmet is a high-quality safety gear specifically designed for equestrian enthusiasts, aimed at providing riders with superior safety and comfort. Whether it's leisure riding, equestrian training, or competitive events, our helmet offers the best protection.Our horse riding helmet not only focuses on safety but also emphasizes comfort and style. Whether you are a novice rider or an experienced equestrian enthusiast, our helmet can meet your needs and become an indispensable safety partner in your riding journey.

Usage Scenarios

Leisure Riding: Provides head protection and comfort for daily riding enthusiasts.

Equestrian Training: Ensures head safety during training and offers good ventilation.

Competitive Events: Offers high-strength protection and a lightweight design to enhance comfort and performance in competitions.

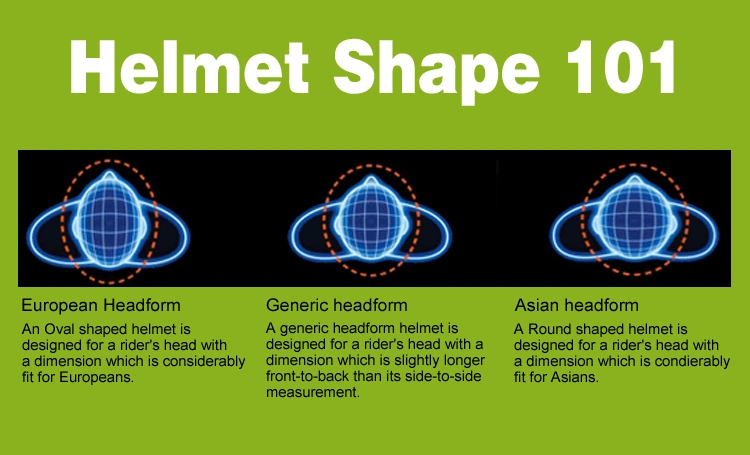

The head circumference knowledge of horse riding helmet:

European Headform:

An Oval shaped helmet is designed for a rider's head with a dimension which is considerably fit for Europeans.

Generic headform:

A generic headform helmet is designed for a rider's head with a dimension which is slightly longer front-to-back than its side-to-side measurement.

Asian headform:

A Round shaped helmet is designed for a rider's head with a dimension which is condierably fit for Asians.

The Specification of horse riding helmet:

Weight: Extremely lightweight and comfortable

Material: ABS hard shell in-mold technology + washable mesh cap + wide brim for enhanced sun protection. Scratch and water resistant outer

Smart honeycomb ventilation system for optimum airflow

Self-adjusting system allows the helmet to perfectly and user-friendly fit on the riders' head, guaranteeing the crucial advantage in terms of safety and wearer comfort with 3 functional performance.

Removable, washable mesh liner

Hypoallergenic, water repellant harness

Certification: CE-EN1384 certified for impact protection.

| MODEL NUMBER | HR02 Horse helmet |

| TECHNOLOGY | PC + America imported EPS foam |

| STRAP | Adjustable Nylon/Tetoron strap for a perfect fitness |

| BUCKLE | ITW durable buckle or FIDLOCK magnet buckle |

| HEAD CIRCUMFERENCE | Xs-S(50-54 Cm); M-L(54-58 Cm); L-XL (58-62 Cm) |

| IMPACT MANAGEMENT | in mold |

| VISOR | Adjustable and removale visor |

| CERTIFICATION | E.U.:CE EN1384 safety standard for helmets |

| FEATURE | Multi-impact, durable lifetime |

| ACCESSORIES | Flexible durable adjustment, adjustable chin strap, Fid lock magnet quick-release buckle; eco-friendly soft pads |

| HIGHLIGHTS | EPS+PC inmold technology |

| TYPE OF USE | horse riding protection, outdoor activties |

Detailed Photos

A RIDING HELMET SHOULD…

• Be SEI certified and meet the ASTM F1163-15 standard. This will be noted by a label permanently attached to the inside shell. Not all helmets meet these standards.

• Be worn at all times when you are mounted.

• Fit as snugly as you can comfortably wear it. The chin strap must touch the rider's jaw and/or chin.

CHOOSE A RIDING HELMET THAT…

• Is appropriate to your riding style.

• Stays on your head when the chin strap is fastened, without moving around.

• While the helmet is secured, try moving the helmet front to back, and side to side; the scalp should move with the helmet, indicating a correct fit.

FOR SAFETY…

• Always ride with your helmet securely fastened.

• Immediately replace any helmet that has a damaged harness or has been involved in serious impact. Damage to the shock absorbing inner layer may decrease the effectiveness of the helmet. This may not always be detected with the naked eye.

Our designers will design the most creative and most innovative helmet in different styles one step ahead the market trends and meets the safety standards, such as CPSC, CE and ASTM.

Our sales department and Customer Services provide all the needs to take care of Quality Control and On Time Delivery for Domestic and International market. What's more, we have our own EPS molding plant, PC printing, thermoforming for the shell and plastic injection facilities to build our sophisticated models, which make our production fully integrated from a conceptual stage to final production assembling.

Factory Size & Workforce

Total area: 18,000 m²

Total employees: 210

Dongguan Factory: approx. 200 staff (50 office staff, 150 production workers)

Yueyang Factory: approx. 150 staff (35 office staff, 115 production workers)

Production Equipment & Capabilities

In-house capabilities include mold manufacturing, printing, vacuum forming, injection molding, in-mold production, painting, labeling, and packaging (partial outsourcing for specialized packaging).

Production Capacity

Daily Output: 5,000 helmets

Monthly Output: approx. 150,000 helmets

Quality Control Process

Pre-production sample completed before mass production

Customer approval based on signed sample

Mass production strictly follows approved reference

Third-party inspection arranged by customers (full inspection or random sampling) before shipment

International Certifications

CE EN1078 | CPSC | ASTM | AS/NZS | UKCA

Annual Sales Turnover

Approx. RMB 95 million

Main Product Categories

Bicycle helmets

Ski helmets

Equestrian helmets

Riot helmets

Industrial safety helmets

Climbing helmets

Water sports helmets

Skydiving helmets

Export Markets

Switzerland, Sweden, Czech Republic, Germany, United Kingdom, United States, Japan, Norway, Italy, France, Netherlands, Indonesia, Singapore, Thailand, and Australia

Key Partners & Brands

SWEET (Norway): Ski helmets, cycling helmets, water helmets, protective helmets

AGU (Netherlands): Cycling helmets, safety helmets

GIANT (China): Bicycle helmets, safety helmets

LIIMAR (Italy): Cycling helmets, safety helmets

Helmet Quality Control Process

At CGPRO Helmets, every helmet undergoes a comprehensive, multi-stage quality inspection process to ensure consistent safety, durability, and international compliance. From raw material to final packaging, we enforce strict control measures to guarantee outstanding product quality for global clients.

1. Incoming Quality Control (IQC)

All raw materials are tested upon arrival to meet strict safety and performance criteria.

EPS foam density & consistency

PC/ABS shell material verification (impact & burn test)

Webbing and buckle tensile strength testing

Non-toxic ink & decal inspection (odor and adhesion check)

2. In-Process Quality Control (IPQC)

We implement process checks at each key production stage to prevent defects from entering the next phase.

Injection molding: Surface flatness, no cracks or shrink marks

EPS shaping: Uniform thickness and bonding quality

In-mold shell & EPS bonding strength

Interior padding alignment, sewing, and glue adhesion

3. Final Quality Control (FQC)

Before packaging, all helmets are fully inspected for overall quality, fit, and function.

100% visual inspection for appearance

Shell stability and deformation test

Strap & adjustment system function test

Size and fitting confirmation using model headforms

4. Laboratory Testing (EN/ASTM/CE/ISO Standards)

Our in-house lab and third-party partners conduct critical safety tests in accordance with international certifications.

Impact absorption test (EN1078 / ASTM F1447 / EN397)

Penetration resistance (EN12492 / EN1385)

Chin strap strength and retention system durability

High/low temperature resistance and UV stability

5. Outgoing Quality Control (OQC)

Before shipping, we conduct random sampling inspections to ensure batch consistency and package integrity.

AQL-based visual & functional check

Barcode, label, and accessory verification

Final inspection report and shipping approval

Case: OEM Polo Helmet with Carbon Fiber Shell & Retractable Visor

Client Need:

In July 2024, a Dubai-based polo helmet client approached us, seeking an OEM & ODM manufacturer capable of delivering a fully customized solution. Their requirements included a wide brim, retractable sun visor, lightweight design, and certification under PAS and SEI standards.

Our Solution:

After a detailed review of the client’s needs, we created a 3D model and produced 3D-printed prototypes to confirm structure and aesthetics. Upon approval, we developed four size molds. To ensure certification readiness while achieving lightweight performance, we recommended a 100% carbon fiber outer shell paired with a high-performance, lightweight EPP liner. The retractable visor was engineered as a signature feature of the helmet.

Result:

The helmet is currently in the testing phase. The client has expressed strong satisfaction with the design and engineering approach, and collaboration is expected to expand once certification is complete.

We have set up a design department in order to meet the different customers;

Our designers will design the most creative and most innovative helmet in different styles one step ahead the market trends and meets the safety standards, such as CPSC, CE and ASTM. Our sales department and Customer Services provide all the needs to take care of Quality Control and On Time Delivery for Domestic and International market. What's more, we have our own EPS molding plant